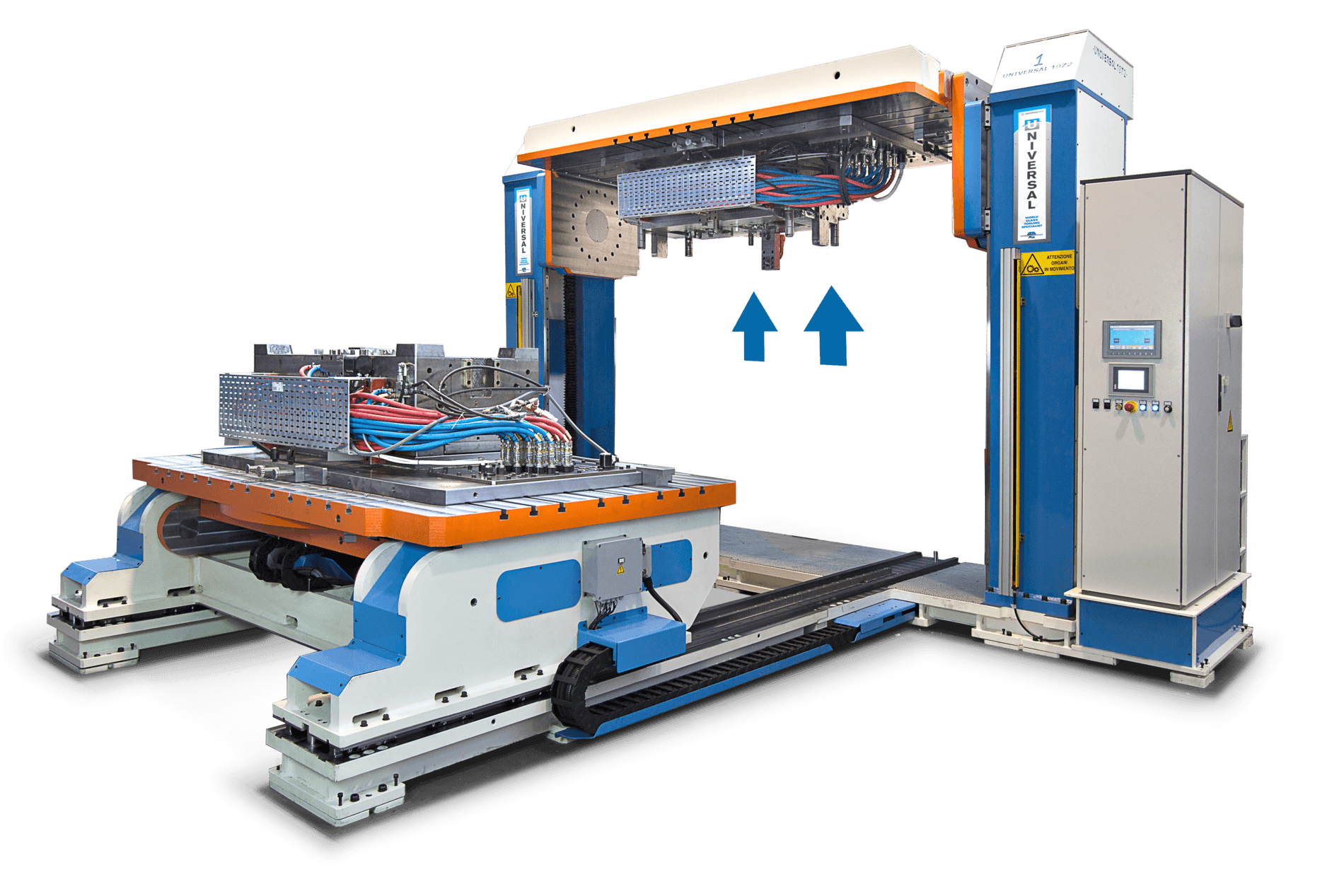

Plastic and die casting mould separator

Innovate the assembly and maintenance of plastic and die casting moulds

Enhance safety and productivity

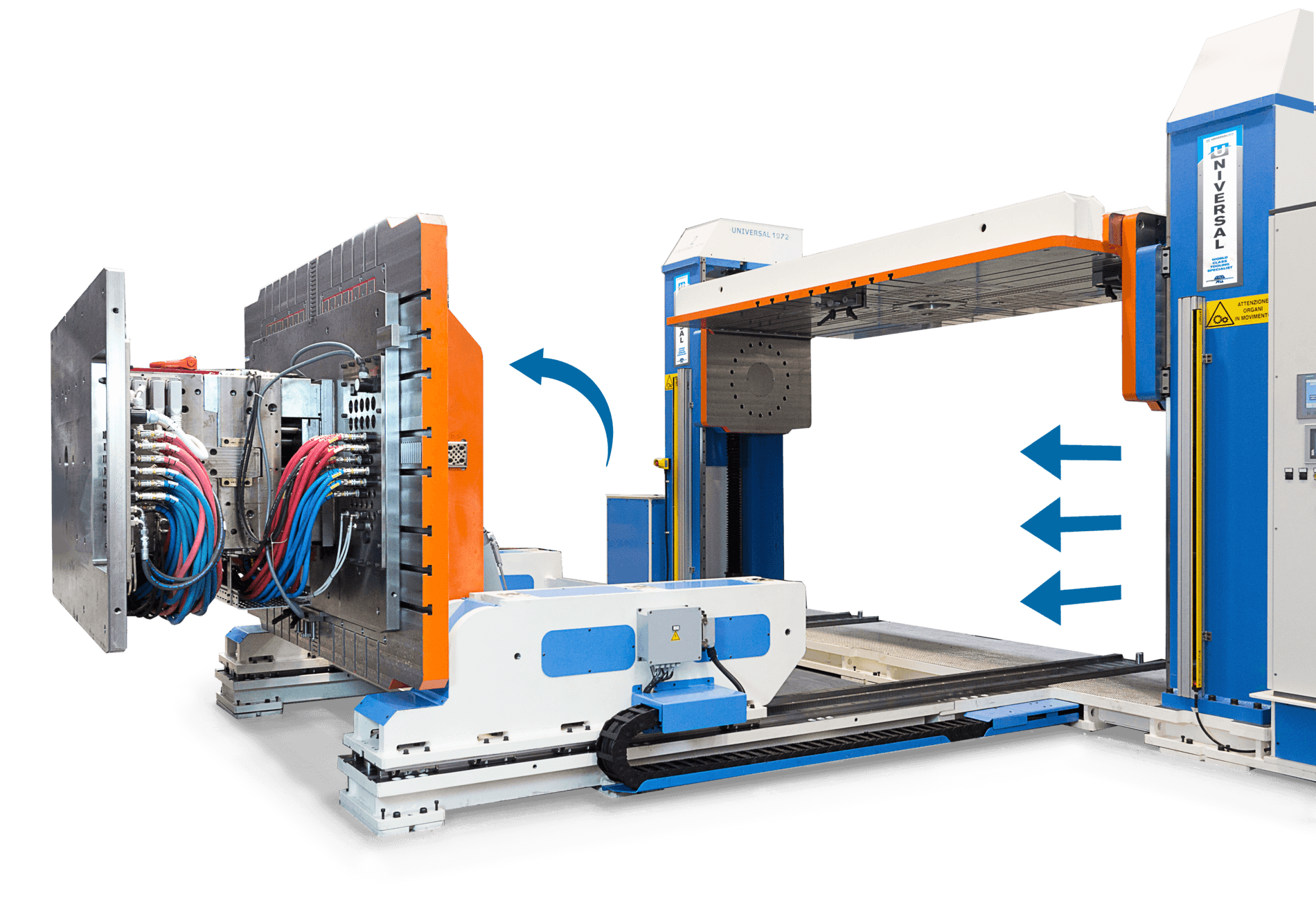

Working with moulds for plastic or die casting can be challenging, as the tools are equipped with injection nozzles and other parts that protrude from the main contour. Manual handling is demanding and routine maintenance operations pose a risk to the safety of personnel.

Our solutions:

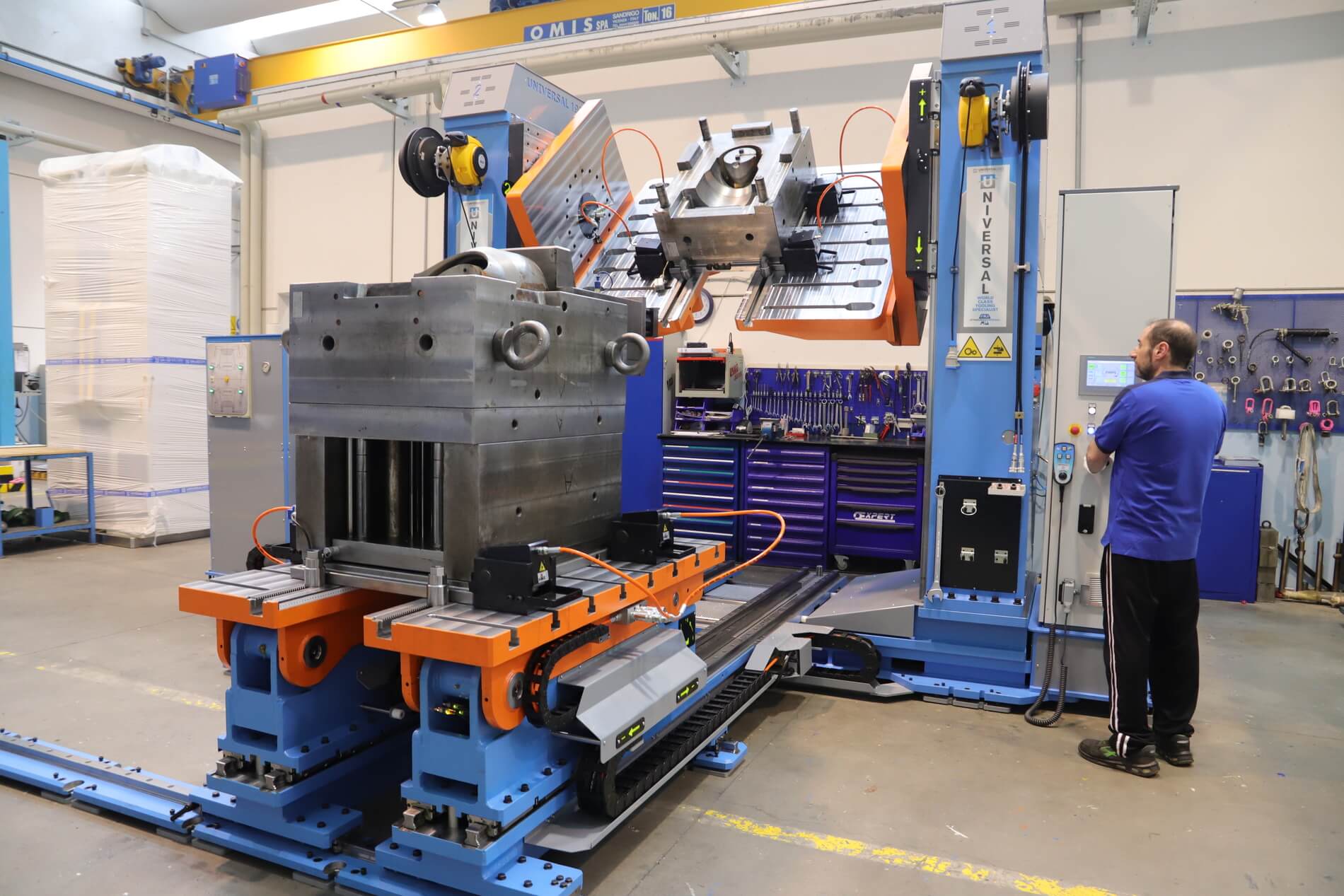

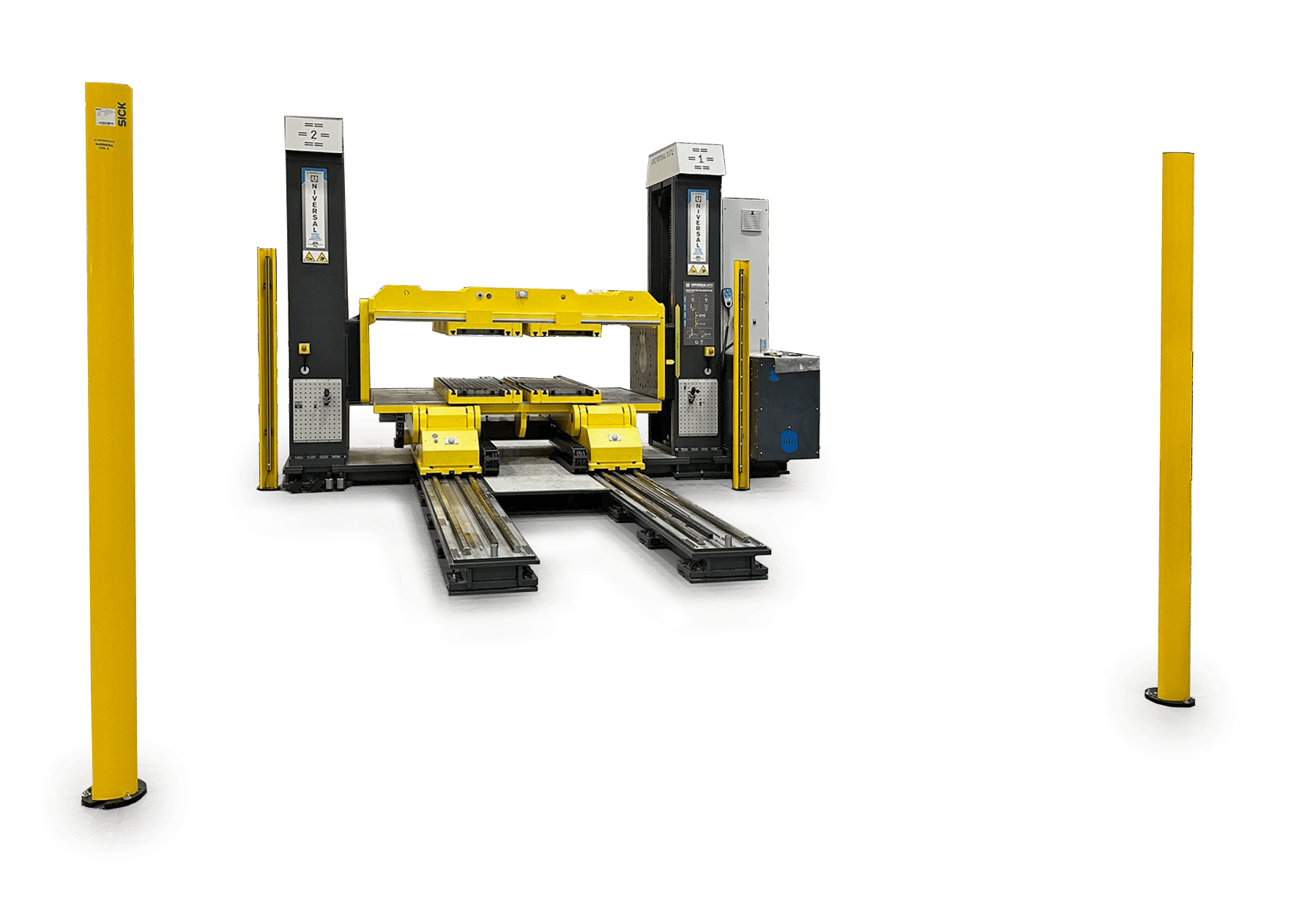

Our Mould separators for plastic and die casting moulds include a range of state-of-the-art devices to handle tools of any size. Tailored to your needs, they combine innovation, versatility and efficiency, integrating seamlessly into automated manufacturing processes and ensuring high safety standards.

50 years of experience at your service:

Thanks to fifty years of experience as toolmakers, we have developed the Mould separator to optimize the work of technicians and diemakers. Our innovative solution facilitates tool maintenance, guaranteeing precise and safe operations and drastically reducing working time.

Advantages

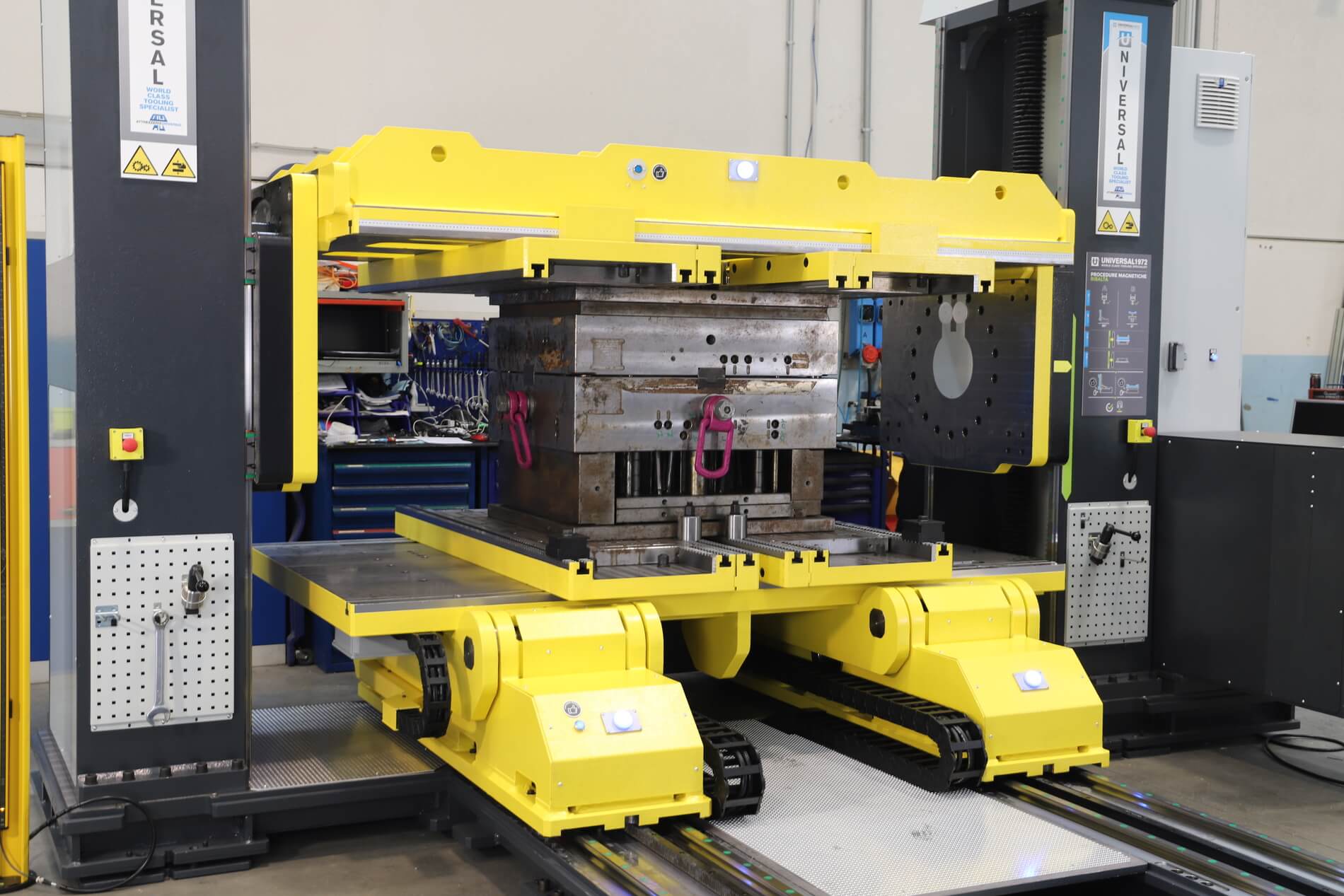

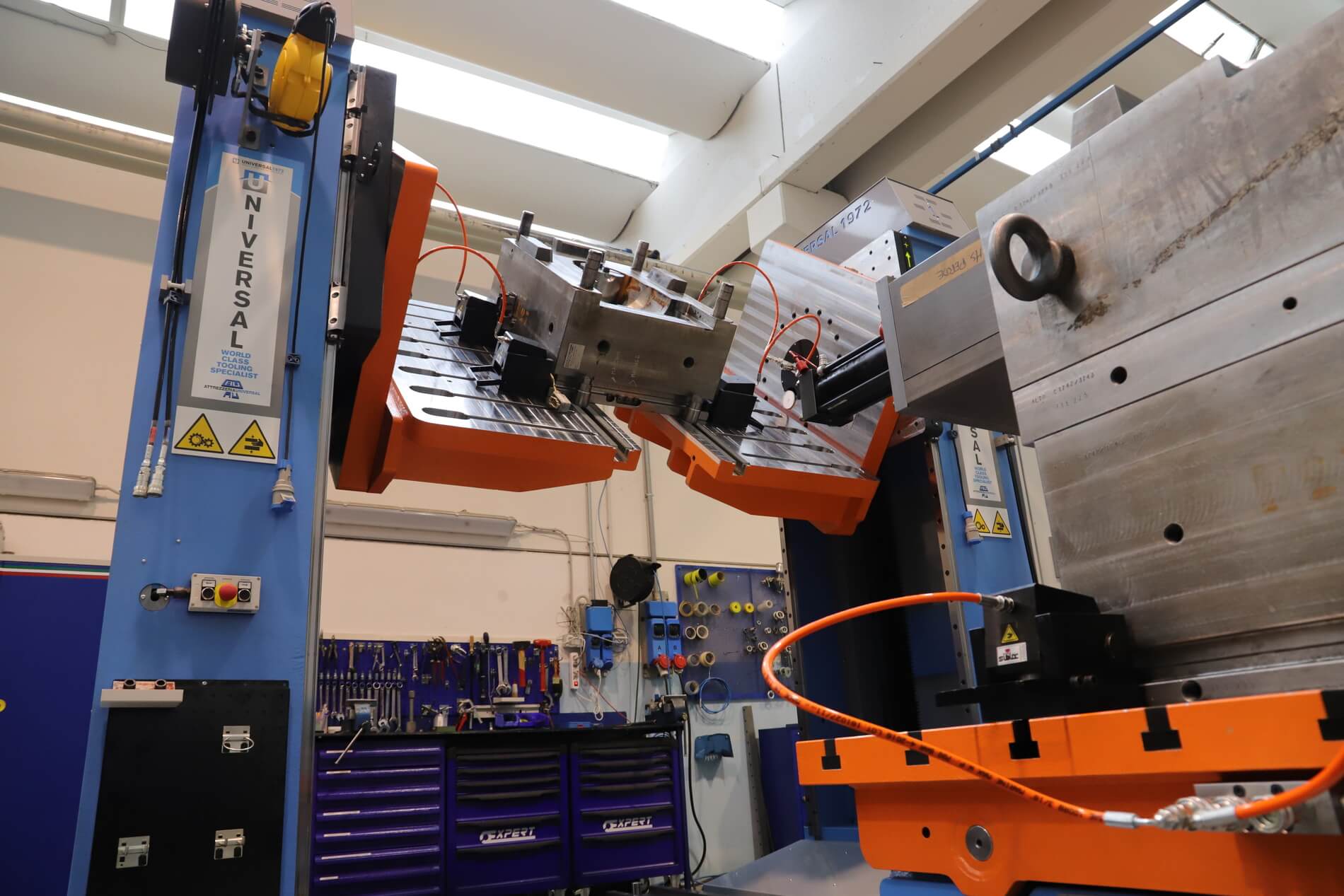

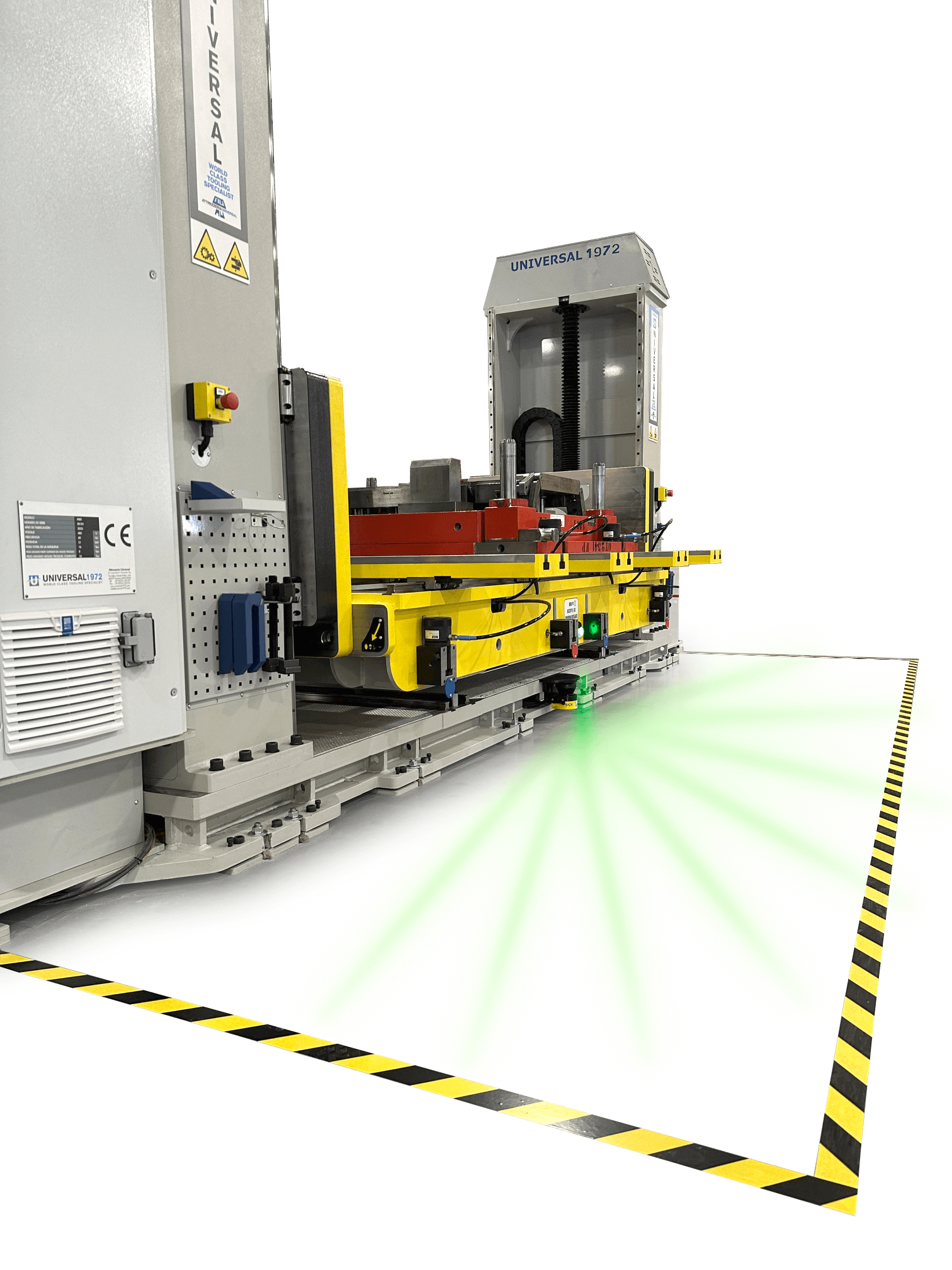

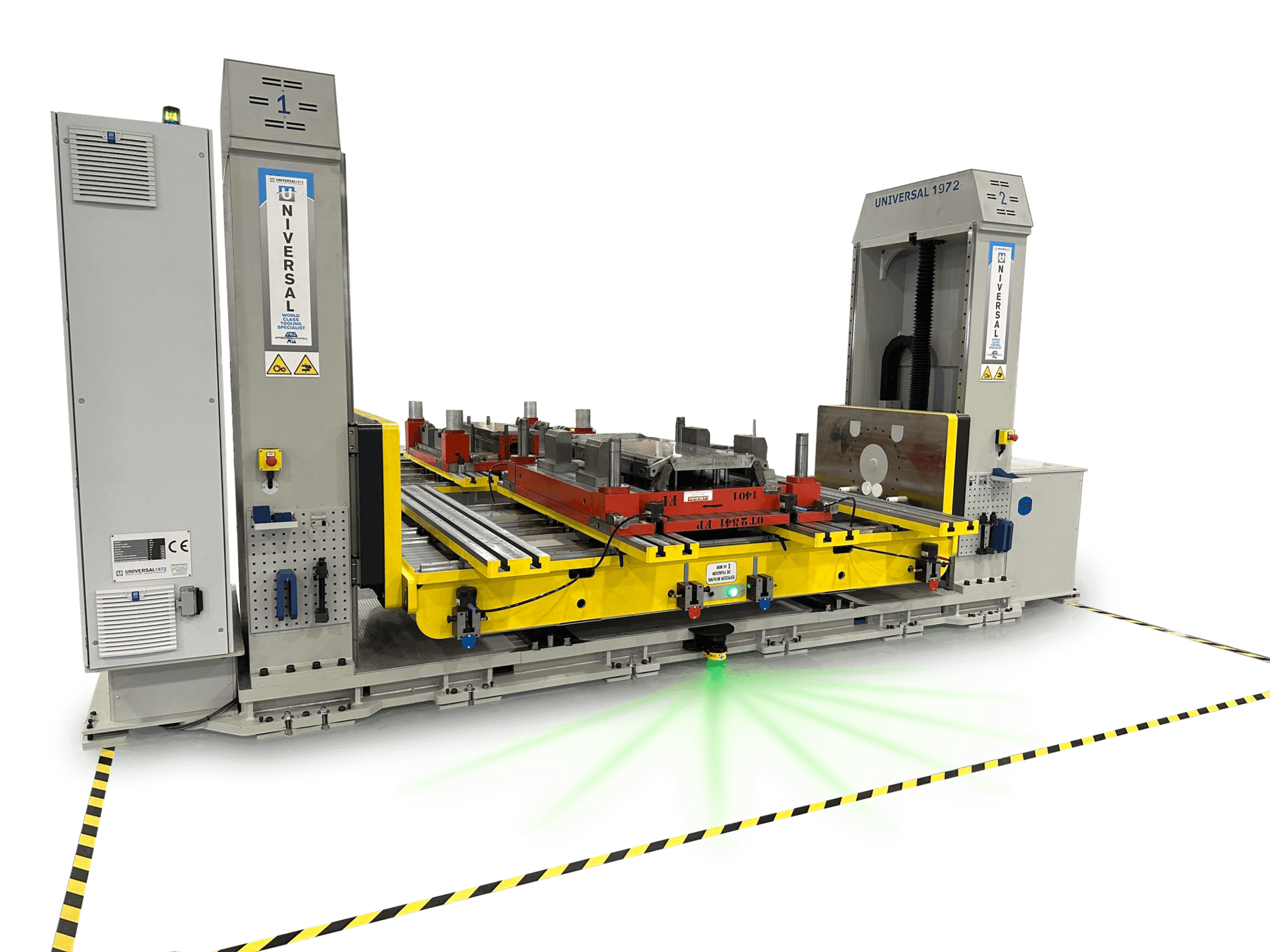

Our Mould splitters are perfect for assembly, adjustment, inspection and repair work on tools. With a robust and stable design, these die splitters provide access to both sides of the tool, facilitating fast and safe operations. The rotation of the half tools allows comfortable working in total safety.

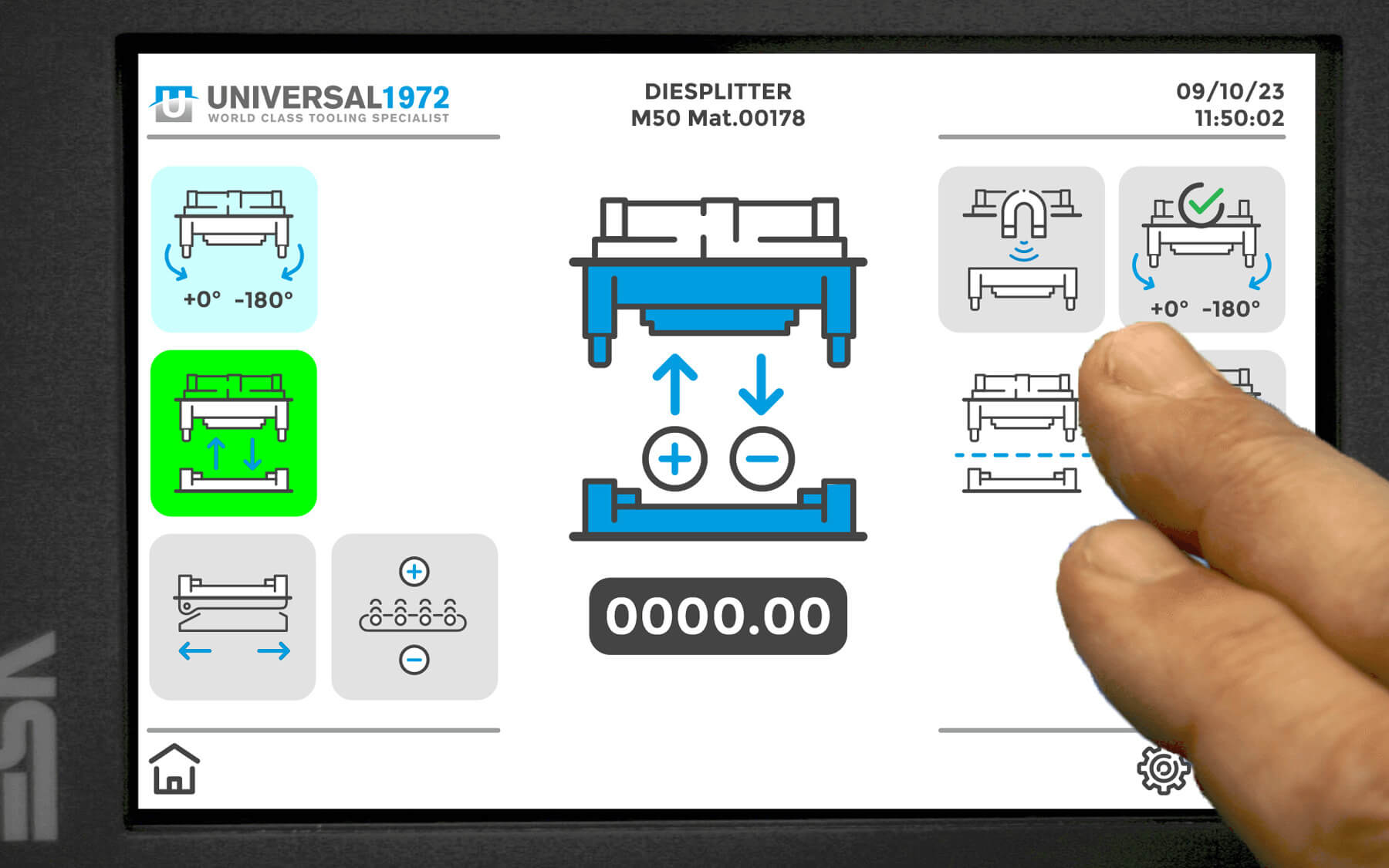

Vertical adjustment is finely controlled for precision and parallelism, and everything is easily managed via a user-friendly touch panel.

Advanced features

User-friendly software

Extra options

Safety

The choice of safety level depends on the risk assessment that is made for each type of machine. The customer may, in turn, request further implementations.

Horizontal opening model

Visit our blog

For more information about Plastic and die casting mould separator, visit our blog!

Time is money!

For this reason (*and for many others)

we have created the Die splitter

Find out how much you can save in a year using our machine!