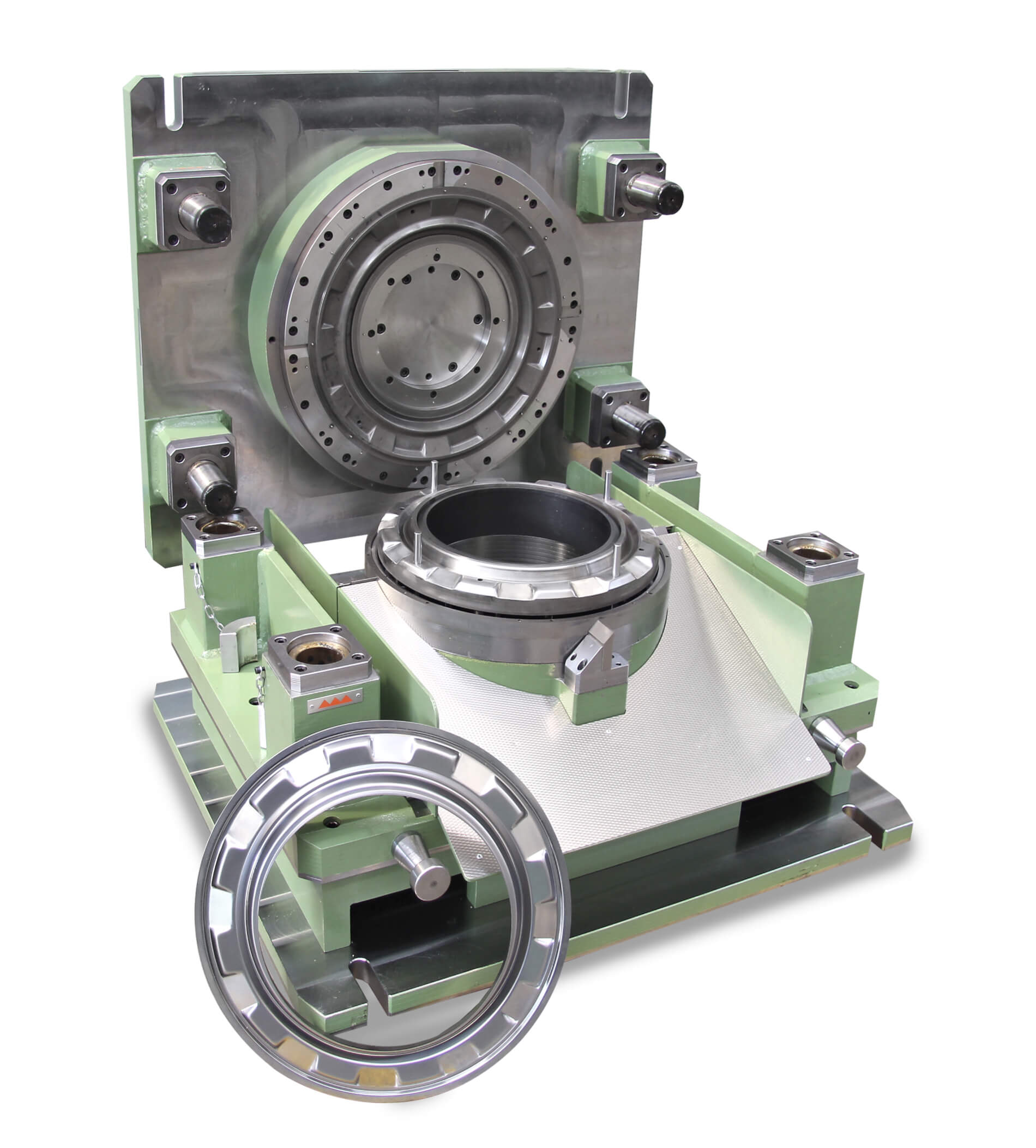

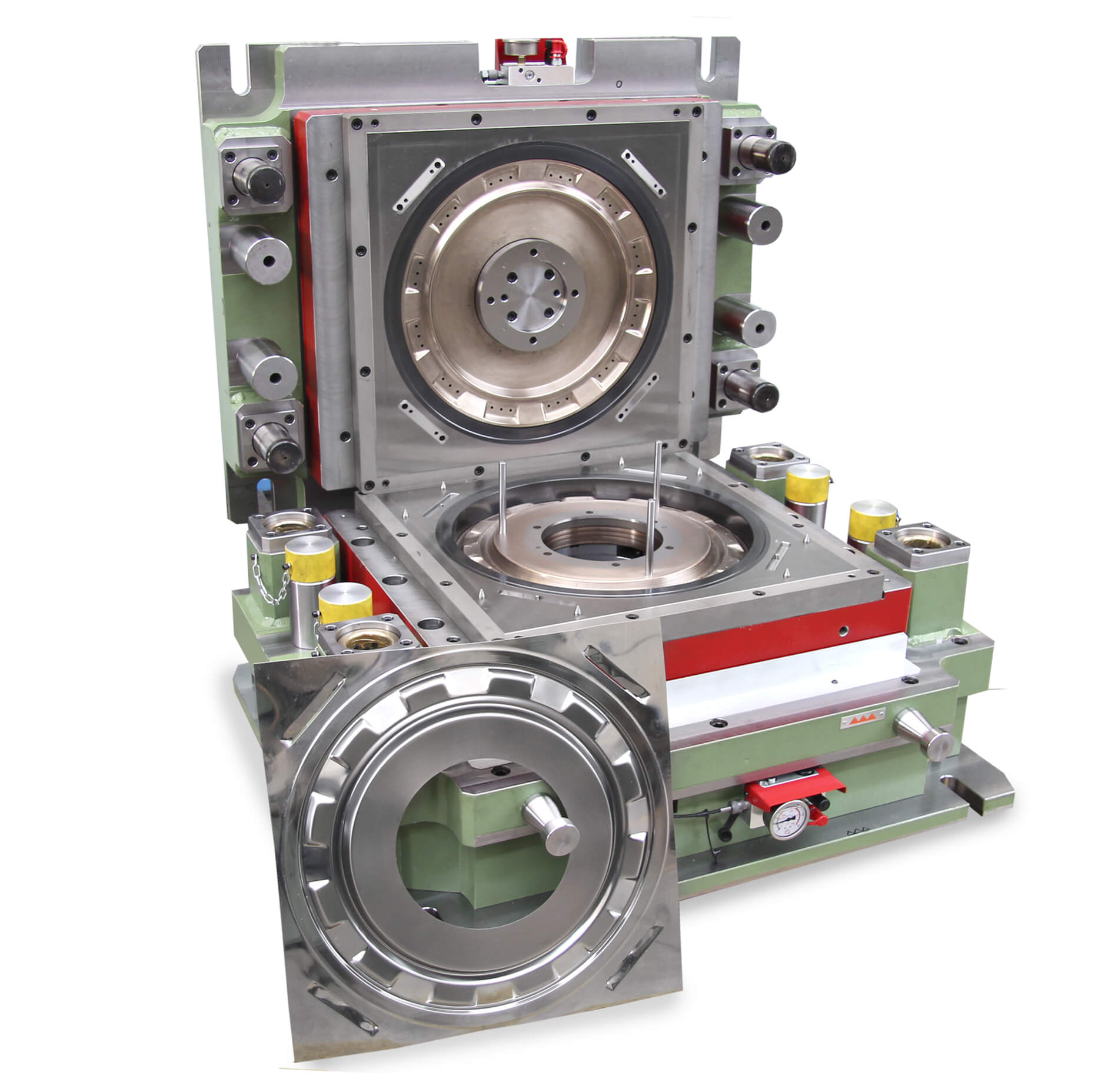

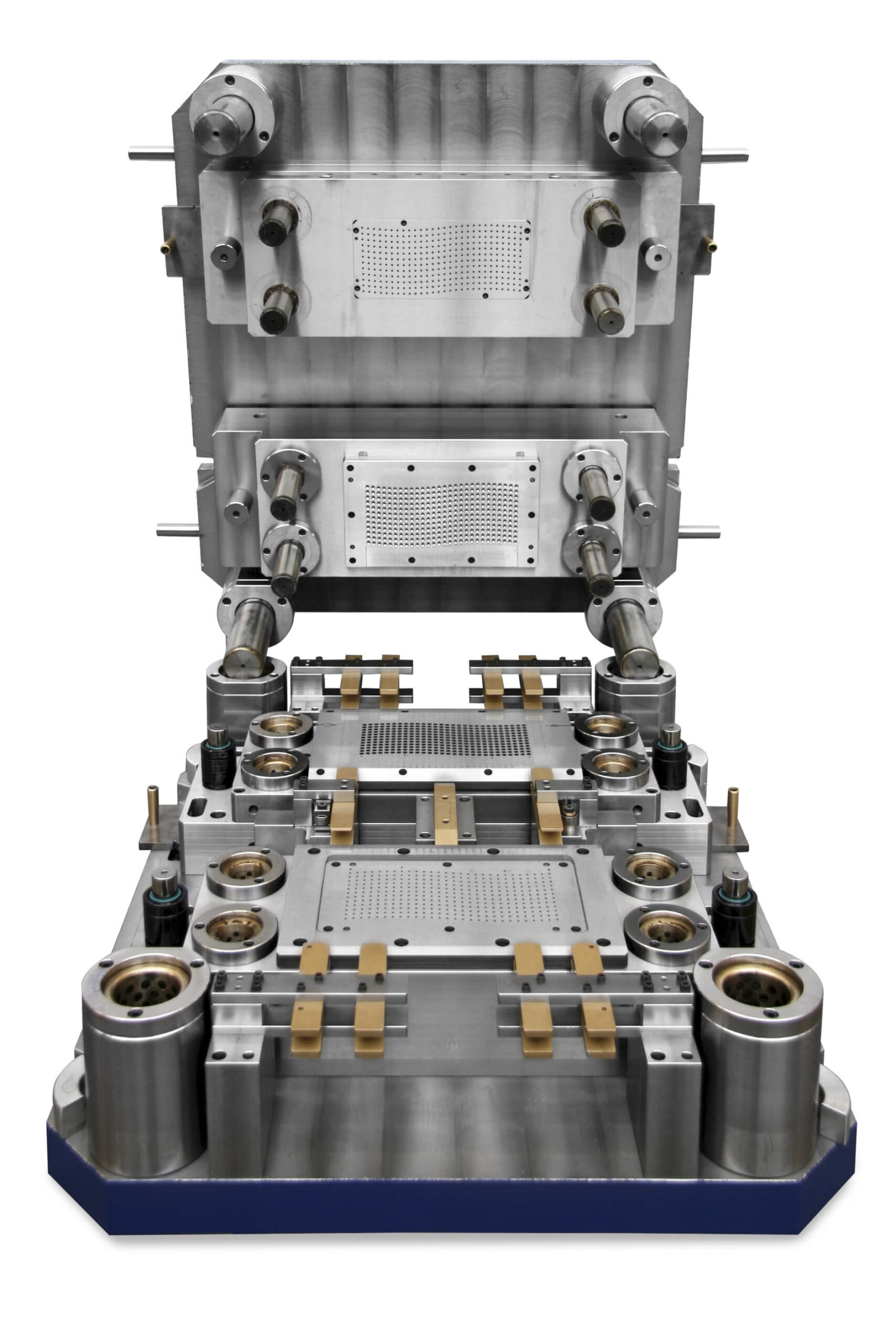

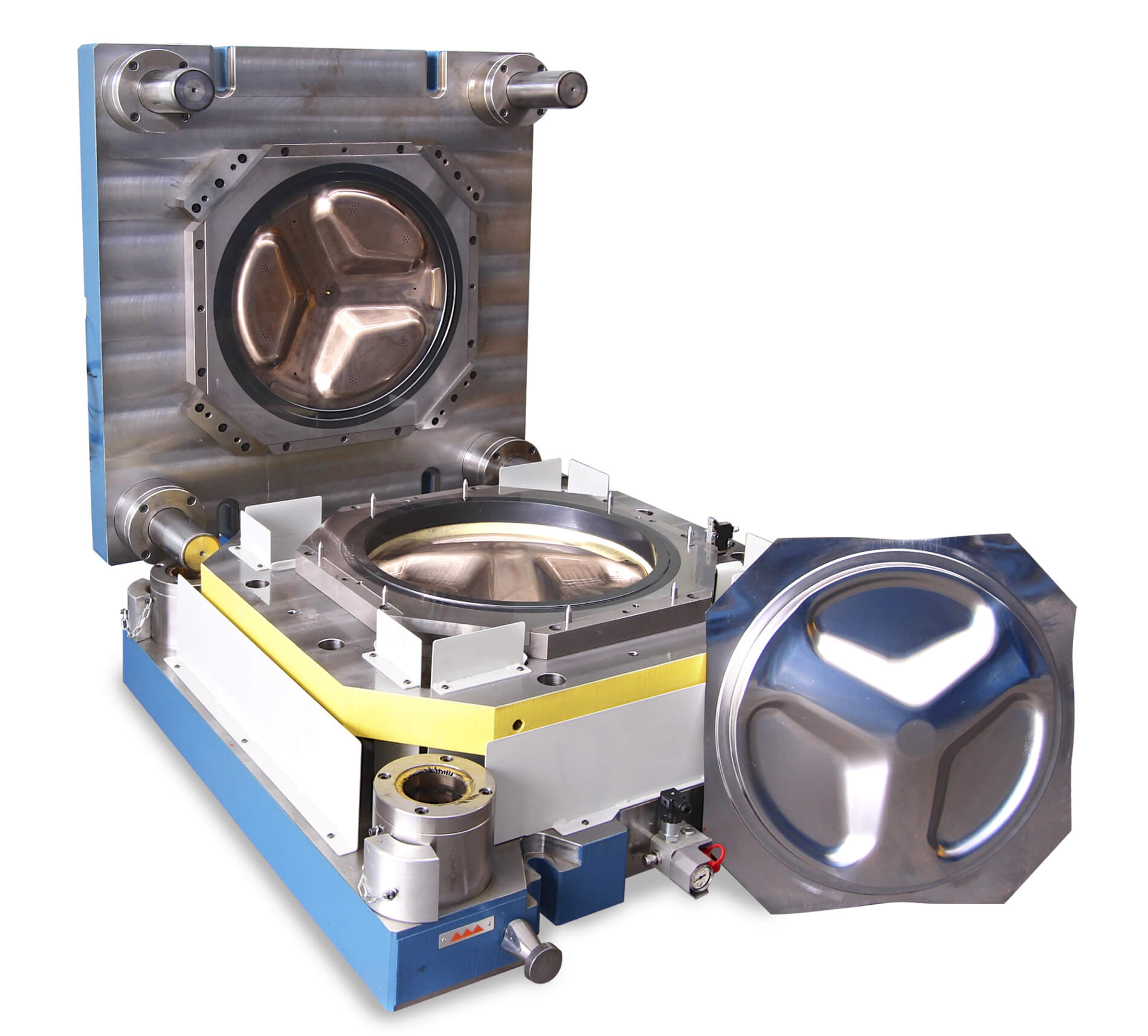

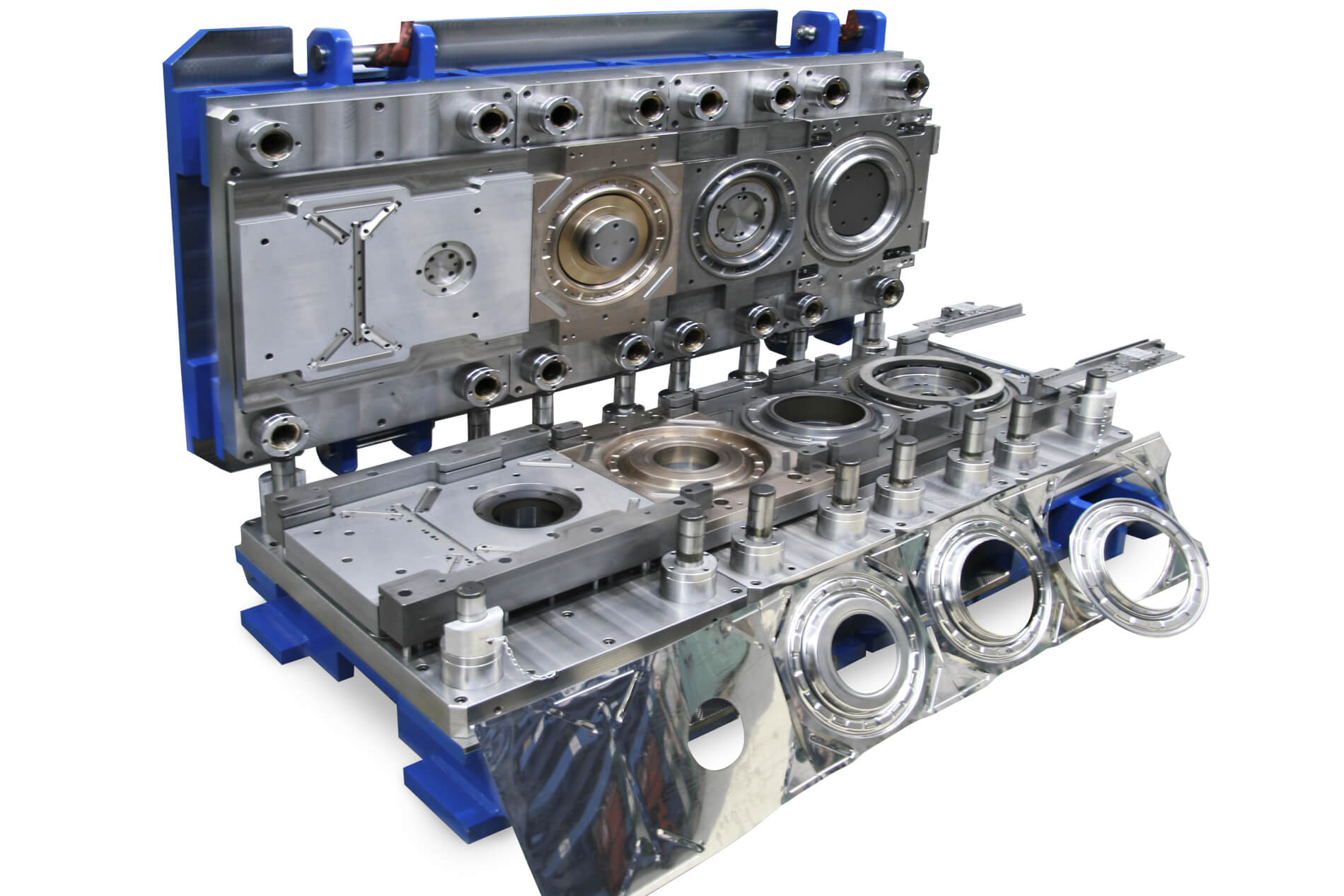

Blanking dies

Are you looking for a company specialising in the construction of customised blanking dies? You’re in the right place! Since 1972, Attrezzeria Universal has been a leader in cold sheet metal forming, offering services in deep drawing, blanking, sheet metal bending, die production, and the creation of finished and assembled products. With a wide range of blanking dies for different sectors, we meet every application requirement.